When it comes to aluminum tractor ramps, understanding weight capacity is paramount. Ignoring this crucial factor can lead to disastrous consequences, as statistics show that improper ramp usage results in numerous accidents annually. To shed light on this issue, this blog will delve into the significance of weight capacity and provide valuable insights for selecting the right ramps. Let’s explore how a clear understanding of weight capacity can enhance safety and efficiency in loading operations.

Understanding Weight Capacity

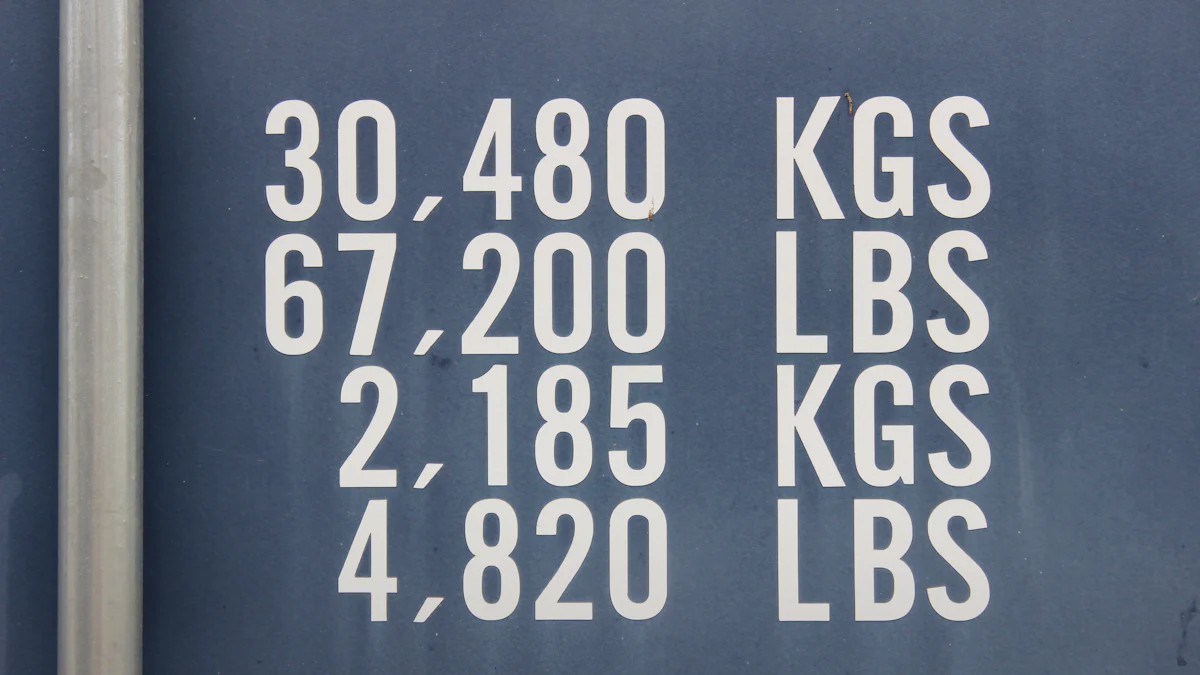

When it comes to aluminum tractor ramps, one must grasp the significance of weight capacity. The weight capacity of these ramps determines the maximum load they can safely support without risking structural integrity. It is crucial to adhere to the specified weight ratings to prevent accidents and ensure operational efficiency.

What is Weight Capacity?

The weight capacity of aluminum tractor ramps refers to the maximum load they can endure without compromising safety. Exceeding this limit can lead to structural failure, endangering both equipment and personnel. Therefore, understanding and respecting these weight limits are paramount for safe loading operations.

Why Weight Capacity Matters

Weight capacity matters significantly as it directly impacts the safety and efficiency of loading processes. By adhering to the specified weight limits, operators can prevent overloading incidents that may result in costly damages or accidents. Choosing ramps with adequate weight capacities ensures smooth loading operations and mitigates risks.

Aluminum Tractor Ramps

When considering aluminum tractor ramps, specific factors come into play that differentiate them from other materials. These ramps offer a unique combination of strength and lightweight properties, making them ideal for various applications.

Specific Considerations for Aluminum Ramps

Aluminum ramps boast impressive features such as durability, corrosion resistance, and ease of handling due to their lightweight nature. Understanding these specific characteristics is essential for selecting the right ramp that aligns with your operational needs.

Comparing Aluminum to Other Materials

In comparison to steel or other materials, aluminum stands out for its high strength-to-weight ratio and versatility in different environments. Professionals in logistics and material handling industries often prefer aluminum ramps for their efficiency and reliability in loading operations.

Factors Affecting Weight Capacity

When considering the weight capacity of aluminum tractor ramps, it is essential to analyze the factors that influence their performance. Two primary aspects play a crucial role in determining the ramp’s ability to withstand heavy loads: material strength and design/construction features.

Material Strength

Aluminum Properties

Aluminum possesses unique properties that make it a preferred choice for manufacturing durable and reliable tractor ramps. Its lightweight nature combined with exceptional strength ensures that aluminum tractor ramps can support substantial weights without compromising safety or structural integrity.

Impact on Weight Capacity

The inherent properties of aluminum directly impact the weight capacity of tractor ramps. By leveraging the strength-to-weight ratio of aluminum, manufacturers can design ramps with higher weight capacities while maintaining a lightweight structure. This enables operators to safely load heavy machinery onto the ramps without concerns about structural failure.

Design and Construction

Structural Integrity

The design and construction of aluminum tractor ramps significantly influence their weight capacity. A robust and well-engineered structure enhances the ramp’s ability to bear heavy loads consistently. Manufacturers prioritize structural integrity to ensure that the ramps can withstand demanding operational conditions without deformation or damage.

Load Distribution

Efficient load distribution is another critical aspect that affects the weight capacity of aluminum tractor ramps. Properly distributing the weight of machinery across the ramp surface minimizes stress concentrations and prevents overloading specific areas. This ensures uniform weight distribution, optimizing safety during loading and unloading processes.

Tips for Selecting the Right Ramps

Assessing Machinery Weight

To ensure optimal safety and performance, assessing machinery weight is a critical step in selecting the right aluminum tractor ramps. Follow these guidelines for a seamless loading process:

- Determine the total load of your machinery by calculating its weight accurately. This step is crucial to match the ramp’s capacity with your equipment’s specifications.

- Matching ramps to machinery requires precision and attention to detail. Choose ramps that can accommodate the weight of your machinery without exceeding their capacity limits.

Regular Inspection and Maintenance

Prioritizing regular inspection and maintenance routines is key to prolonging the lifespan of your aluminum tractor ramps. Here are essential practices to uphold:

- Recognize the importance of inspections in ensuring that your ramps are structurally sound and safe for use. Regular checks help identify any potential issues early on.

- Implement maintenance best practices to keep your ramps in top condition. This includes cleaning, lubricating moving parts, and addressing any signs of wear or damage promptly.

By adhering to these tips, you can make informed decisions when selecting aluminum tractor ramps, promoting safety, efficiency, and longevity in your loading operations.

- In summary, understanding the weight capacity of aluminum tractor ramps is paramount for safe loading operations.

- Prioritizing safety and efficiency ensures smooth loading processes and prevents accidents.

– When selecting ramps, always consider weight limits to guarantee optimal performance and longevity.