Aluminum ramps for vans play a crucial role in enhancing accessibility and safety. The ramps, designed with high-traction surfaces, ensure stability during loading and unloading processes. Their strength is a key factor, allowing them to support heavy loads with ease. A statistical analysis further validates their reliability and durability in real-world applications.

The Importance of Strength

When it comes to safety considerations, the primary focus is on preventing accidents and ensuring stability. By prioritizing these aspects, the risk of mishaps during loading and unloading processes is significantly reduced. The robust nature of aluminum ramps plays a crucial role in maintaining a secure environment for cargo handling.

In the realm of cargo handling, aluminum ramps excel in accommodating heavy loads and enduring frequent use. Their high-strength properties enable them to withstand the pressures exerted by substantial weights, making them a reliable choice for various applications. Whether it’s transporting goods or equipment, these ramps provide a sturdy platform for seamless operations.

Within suspensions, aluminum ramps contribute to effective load distribution and enhanced durability. By evenly distributing the weight across their structure, they mitigate strain on specific areas, promoting longevity and efficiency. This feature not only ensures the safety of the cargo but also prolongs the lifespan of the ramp system itself.

Aluminum ramps are not just tools for accessibility; they are pillars of strength that uphold operational integrity and safety in cargo management scenarios.

Design and Materials

High-Strength Aluminum

Aluminum and steel are two of the most widely used metals across the manufacturing industry. Aluminum is more expensive than steel, but it is lightweight, strong, resistant to cracks and breaks, and naturally protected against rust. This combination makes it a cost-efficient and quality material for ramps. Although steel is known for its sheer strength due to a higher concentration of carbon, aluminum offers durability without the bulkiness.

Material Properties

- Aluminum: Lightweight yet robust

- Steel: Known for its sheer strength

Manufacturing Process

- Aluminum: Cost-efficient and quality product

- Steel: Bulkier but extremely tough

Structural Design

When considering the structural design of ramps, load-bearing capacity and weight distribution play vital roles in their effectiveness. Aluminum ramps are designed to last indefinitely without the need for repair. They can withstand daily usage with ease, making them a reliable choice for various applications.

Load-Bearing Capacity

- Aluminum ramps: Indefinite lifespan

- Steel ramps: Known for their toughness

Weight Distribution

- Aluminum ramps: Evenly distribute weight

- Steel ramps: Resilient under pressure

Find the Right Ramp

Finding the right ramp involves considering factors like length, width, and weight capacity. Aluminum ramps offer added safety features such as 3-inch runoff curbs compared to fiberglass ramps’ 1-inch runoff. Additionally, aluminum loading ramps feature shark tooth decking for a non-slip surface.

Length and Width

- Choose based on van size requirements.

- Ensure compatibility with cargo dimensions.

Weight Capacity

- Consider maximum load requirements.

- Opt for high-strength materials like aluminum.

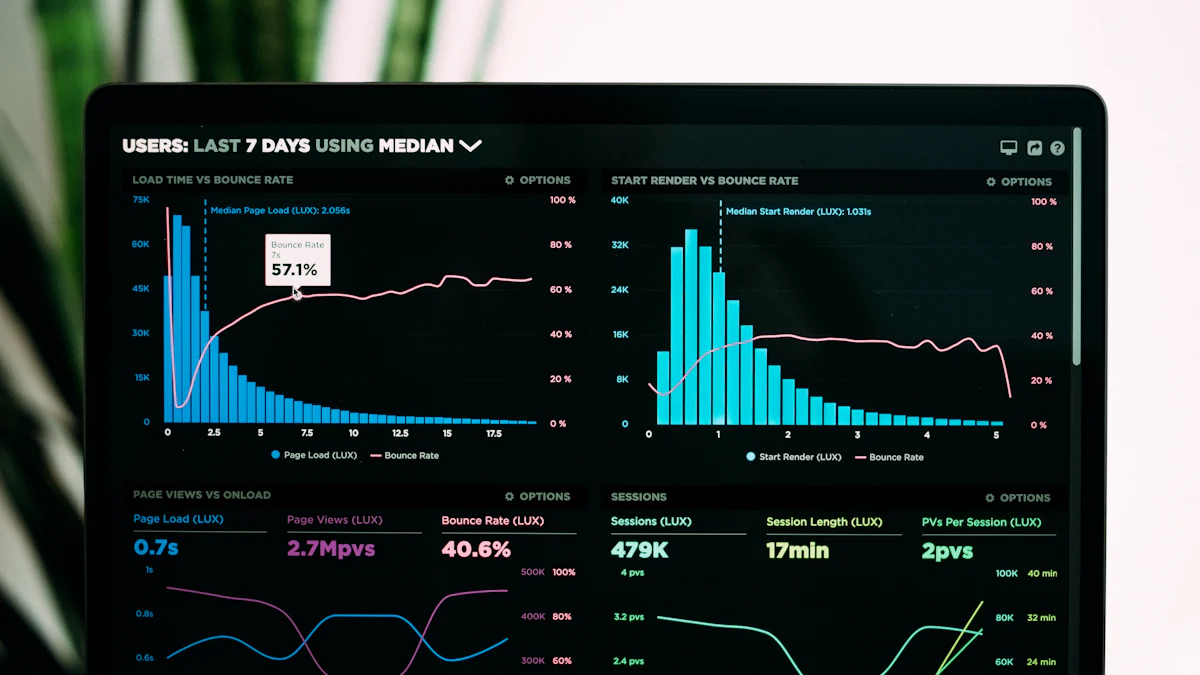

Statistical Analysis

Data Collection

Sample Size

- Aluminum ramps’ strength was assessed through a comprehensive data collection process. The sample size included various ramp configurations to ensure a thorough analysis. Different lengths and weight capacities were considered to provide a holistic view of the ramps’ performance under varying conditions.

Testing Methods

- To evaluate the strength of aluminum ramps accurately, rigorous testing methods were employed. These methods involved subjecting the ramps to incremental loads to determine their maximum capacity. By simulating real-world scenarios, the testing ensured that the ramps could withstand demanding usage without compromising safety.

Results Interpretation

Strength Metrics

- The statistical analysis revealed compelling strength metrics for aluminum ramps compared to other materials. The high-strength aluminum exhibited exceptional load-bearing capabilities while maintaining its lightweight properties. This combination of strength and adaptability positions aluminum as a superior choice for van ramp applications.

Comparison with Other Materials

- When comparing aluminum ramps with steel alternatives, the analysis highlighted key differences in material properties. While steel is known for its toughness due to a higher carbon concentration, aluminum offers durability without sacrificing malleability. Additionally, when contrasted with fiberglass ramps, aluminum loading ramps emerged as more cost-efficient and durable options with enhanced safety features.

Practical Implications

Real-World Applications

- The statistical findings have significant implications for real-world applications of aluminum ramps in cargo management scenarios. Their robust construction and high-traction surfaces make them ideal for safely loading heavy equipment or goods onto vans and trucks. Moreover, the portability and adaptability of aluminum ramps enhance operational efficiency across various industries.

Future Developments

- Looking ahead, advancements in manufacturing processes can further improve the design and strength of aluminum ramps for vans. Innovations such as enhanced surface treatments or alloy compositions could elevate the performance standards of these essential loading tools. By focusing on continuous development, future iterations of aluminum ramps are poised to set new benchmarks in strength and reliability within the industry.

Recap of the importance of strength in aluminum ramps for vans

- Aluminum ramps are essential for ensuring safe and efficient loading and unloading processes.

- The high-strength properties of these ramps guarantee stability and reliability in various cargo handling scenarios.

Summary of key findings from the statistical analysis

- The statistical analysis confirmed that aluminum ramps excel in load-bearing capacity and durability.

- Compared to other materials, high-strength aluminum stands out for its robustness and adaptability.

Future recommendations and potential developments

- Emphasizing continuous advancements in manufacturing processes to enhance ramp design.

- Exploring innovative surface treatments or alloy compositions for extended ramp longevity.